Company

CEMB‘s core business incorporates all industrial applications inherent to vibration analysis: the Industrial Division of CEMB develops, manufactures and exports worldwide a range of vertical axis and horizontal axis balancing machines, produces fully automated high-tech machines specifically dedicated to assembly-lines of automotive manufacturers; this latter field is in continuous growth thanks to the contribution of our Hofmann sister company located in Germany.

The Garage Equipment Division handles wheel balancing machines, tire changers and alignments for cars, trucks and motorcycles.

The Vibration Division manufactures vibration sensors, stationary and portable equipment for vibration measurement and analysis, balancing in service conditions, 24h monitoring and control of vibration to protect large machinery in the energy and industrial plant fields such as gas turbines, compressor pumps and motors.

Since 1946 the headquarters have always been located in Italy, at Mandello del Lario, on the eastern shore of Lake Como. Over the years the production facilities and R&D departments have extended and modernized, in connection with the company growth and substantial investments to preserve both heart and style in Italy.

The company, the entrepreneur.

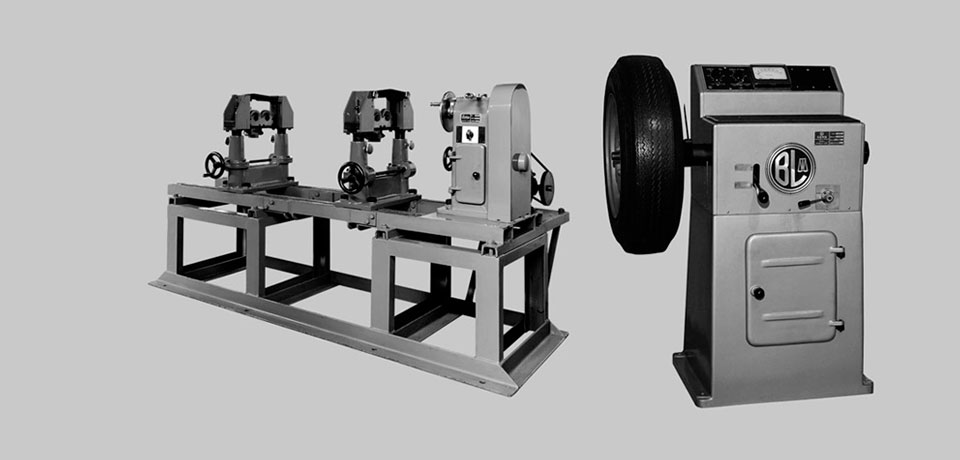

In 1946 Luigi Buzzi designed the first balancing machine with a revolutionary solution, covered by patent. From 1946 to 1949 he built up the production of mechanical resonance type balancing machines followed by stroboscopic types particularly distinguished for their sensitivity and robust manufacture. Production was started in 1952 with balancing machines for motor vehicles. In 1954 CEMB commenced the production of balancing machines based on wattmeter electrodynamic system, which is still considered as one of the most reliable. In 1960 he encouraged the constitution of an R&D department in the rapidly growing field of electronics: the immediate result was the application of new technologies to traditional systems as well as to monitoring and supervisory instrumentation for large scale power plants. 1969 saw the start-up of the production of rigid pedestal machines which paved the way for new developments. Over the years the organizational and managerial activities have expanded even so Luigi Buzzi has not given up his life-long passion: personal commitment in the design and development of new solutions.

1946

Ever since its establishment in 1946 thanks to the initiative of Luigi Buzzi, CEMB has exhibited the signs and characteristics which have enabled it to achieve a principal role in the production of balancing machines. Especially the ability to combine the requirements of both customer and the market. The ability to produce original and innovative technical solutions. Enthusiastic adaptation of organizational structures and production processes towards a single objective: the maximum quality of the product.

CARLO BUZZI. Continuing development.

Carlo Buzzi is a graduate in engineering at Milan University who joined his father's company in 1977, which was the time of the great computer revolution which was destined to change radically all the old production and control processes. Alongside his father in the running of the company, Carlo Buzzi gave a considerable boost to new designs based on the latest digital technologies. Microprocessor applications were conceived for automatic control of the balancing machines: real time measuring of operative and tolerance parameters, automatic eccentricity correction, automatic correction of the unbalances, prerecorded balancing programs, graphic display of the processing data and statistics. “All of this together with processor-controlled wheel balancing machines are also designed”, as well as computerized systems for motor vehicle diagnostics. Portable computerized vibration monitoring and testing instruments were produced. High precision monitoring and supervisory systems were developed. The application of the new technologies has in no way changed the basic policy: that of assuring the final quality by continuously monitoring the quality of the individual phases. For this reason, the entire engineering process is entrusted to the managers, technical staff and the workers employed within the company: from the original analysis to the project, from the manufacture of mechanical parts to that of electrical components, from the digital control boards to the monitoring processes. Thanks to this quality policy, CEMB currently represents the benchmark for the entire world market. And thanks to this quality, CEMB currently exports its products throughout the world.

Production.

The CNC machinery used by CEMB in the production phase are the very best the market has to offer.

These are machines embodying the latest technological developments, exclusively with numerical control. Only in this way can CEMB guarantee total control over the quality of the critical parts on the balancing machines.

Moreover the machines tools are continually being renewed in order to achieve the continued and constant manufacture of high precision components which has always distinguished the CEMB production.

Design.

To anticipate market requirements. To propose original and innovative technical solutions. To pursue the high-test quality of products. To be able to achieve these objectives, CEMB re-invests a considerable percentage of its turnover. Over the years the company has created a highly professional and experienced technical staff which today includes thirty high qualified engineers. The CEMB specialists follow each new project step-by-step with the aid of sophisticated data processing systems: from the analysis of the characteristics to the definition of the specifications, from the implementation of a prototype to the performance tests. With a climatic chamber is able to reproduce all climates existing on the earth, at any latitude or altitude and with any degree of ionization this means the new machines can be tested under actual service conditions.